- oramax@oramax.sk

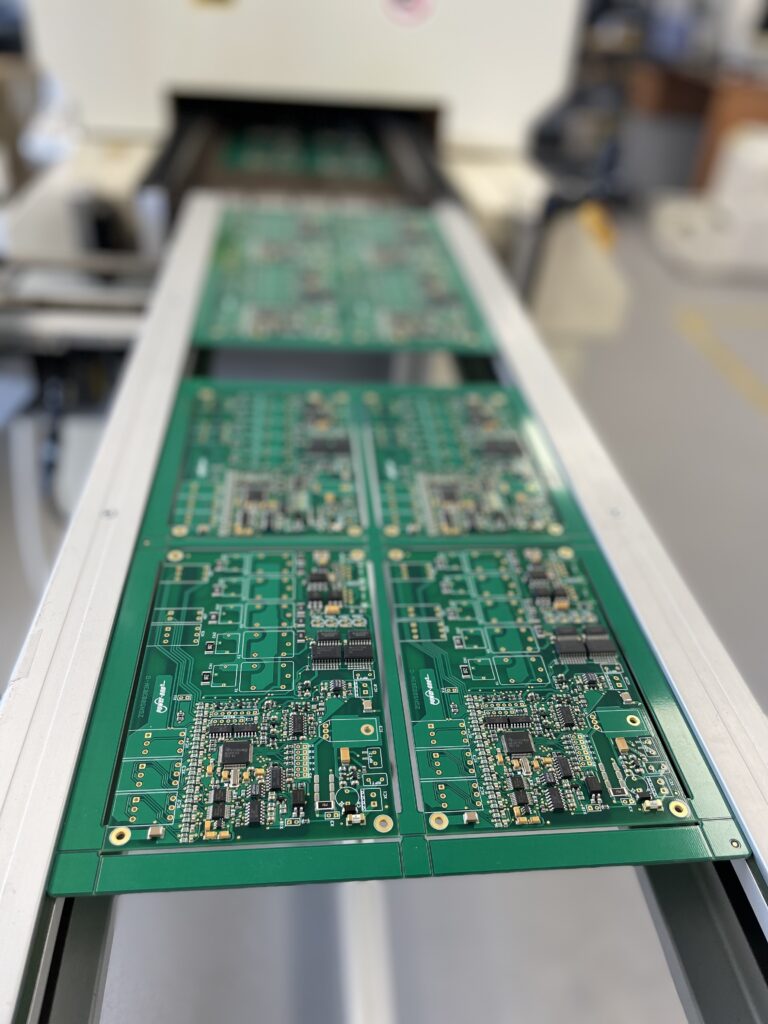

Flexible and Cost-Effective Surface Mount Technology (SMT)

Our PCB assembly is carried out in a well-organized and clean manufacturing environment, structured according to 5S principles. The production hall is ESD-protected with controlled humidity and temperature.

✅ Manufacturing according to IPC-A-610 standards – We offer complete solutions from prototypes (1 piece) and small-batch production to mid-sized series in the thousands.

✅ Product traceability – Levels of traceability based on customer requirements.

✅ SMT Line Capacity – 10,000 components per hour (cph) + fast model change/reconfiguration.

✅ Component Placement – From 0402 up to SOP, SOJ, PLCC 25 mm. Flexible scheduling with 30% blockable capacity. Production from single-unit prototypes to mid-size series.

Automated SMT Line:

- DEK 265 – Solder paste application

- ASSEMBLEON / YAMAHA ORION – SMT machine for small & medium series

- DIMA PASSAAT – Reflow oven

- SAKI – Automated Optical Inspection

- THT Workstations – For manual assembly & soldering

- Component forming & trimming

- ERSA Soldering Stations

- Automatic wire cutting & crimping

- Flat cable assembly, stripping & crimping

- Potting & Overcoating – Encapsulation & coating

- Printer TEC & TampoPrint – Marking & labeling

📌 Capacity: 10,000 cph

📌 Max PCB size: 440mm x 407mm

📌 For small series, we guarantee SMT assembly within 72 hours.